CUTTING MACHINES FOR RUBBER SLEEVES

Rubber Sleeve Cutters: source technology TG6

Our Rubber Sleeve Cutting Machines are very versatile and adaptable to customer needs.

DATASHEET TG6 110 Brushless | Rubber sleeve cutting machine

Rubber sleeve cutting machine

- Max. machining length: 140mm

- Max. machining diameter: 110mm or more with less mandrels

- No. 6 sleeve-holding spindles, with electronically variable speed 3000 rpm/1'

- Cutting system: with lance tools or special steel circular discs outer diameter 80-100 mm

- Horizontal positioning of the sleeve on the loading unit by operator

- Cutting carriage on recirculating roller guides, driven by brushless motor and backlash-free recirculating screw

- Forced lubrication system included

- Brushless motors and drives : Siemens

- Vertical cutting slide sliding on recirculating roller guides driven by Brushless motor and backlash-free recirculating screw

- Unloading of cut washers from racks by operator

- Perimeter protection

- Operator panel for manual commands, diagnostics, data setting, etc.

- PLC-controlled functions.

- Voltage 400 V - 50 Hz

- Auxiliary voltage 24 V

- Installed power: 5 Kw

OPTIONALS

- Automatic loading unit

- Automatic washer unloading unit from the extractor unit for coupling with device quality and dimensional control

Alges and Rubber Sleeve Cutters

SORGENT TECHNOLOGY TG6

Dear Customers and Users,

Alges informs you that in the year 2022 and 2023, by improving the consolidated technology of a company now missing/no longer present in the commercial panorama and with which Alges has collaborated and cooperated in partnership for years, it has specialized in production of rubber sleeves cutting Machine. The first machine, already mass-produced and improved on loading safety conditions, is already available: TG 6M 110 Brushless.

Other models are in the pipeline, such as automatic 2-spindle machines with automatic loading, and we are available to develop and manufacture other models and automatic and customised islands with partial or total kmzero cutting, washing, control and packaging.

We are pleased to present you our TG 6M 110 Brushless.

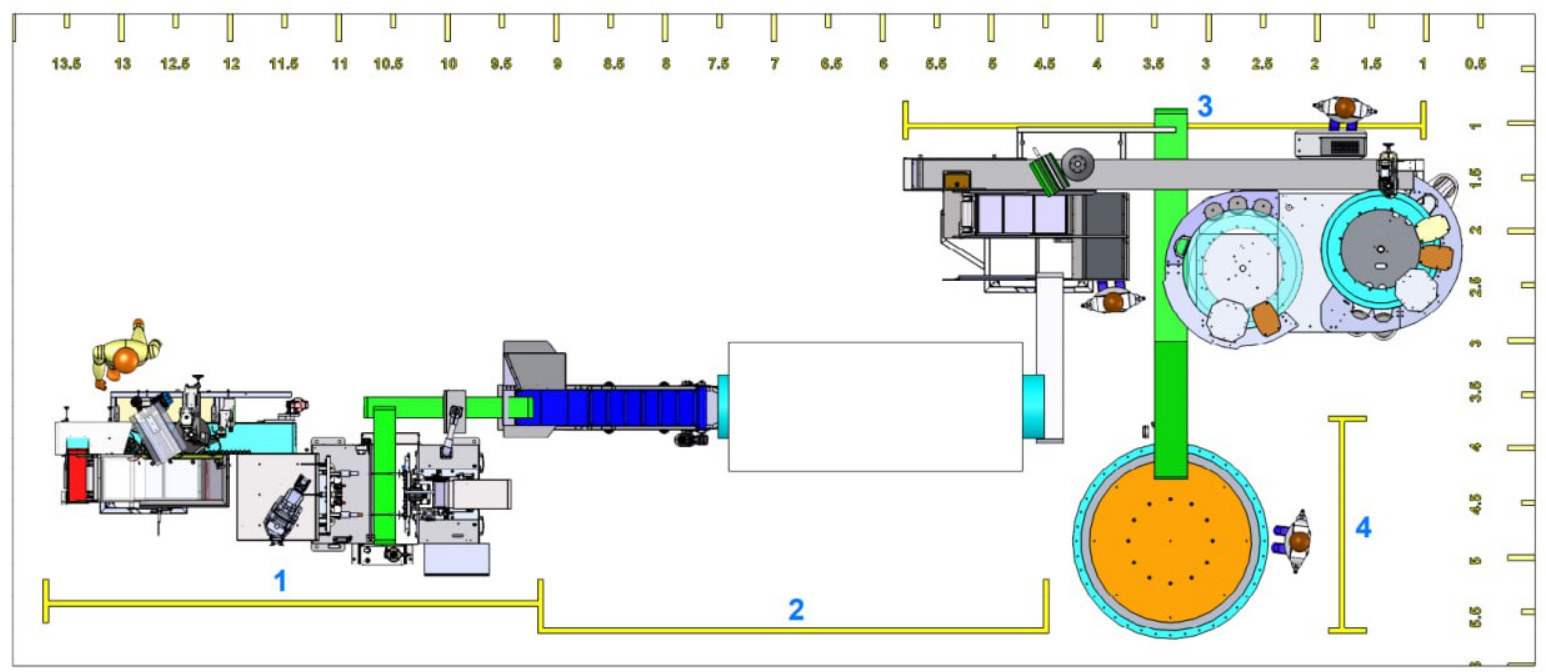

Automatic and customized islands with cutting, washing, control and packaging

KM Zero LEGENDA:

- Automatic LOADING system aligned with TG2 spindle cutter (or others).

- Continuous WASHING system complete with loader.

- Vision machines for QUALITY control on both sides and HEIGHT control over the entire circumference, various models.

- PACKAGING system of various types

Over the years, ALGES has developed experience on various types of machines, all related to the production and processing of seals.

Today ALGES is able to offer in-line systems with zero indirect product handling.

This layout is an example that from the moulded sleeve takes us through cutting, washing, quality control and packaging.

What are your needs?

What we know how to do we demonstrate it with facts.